Stage 1

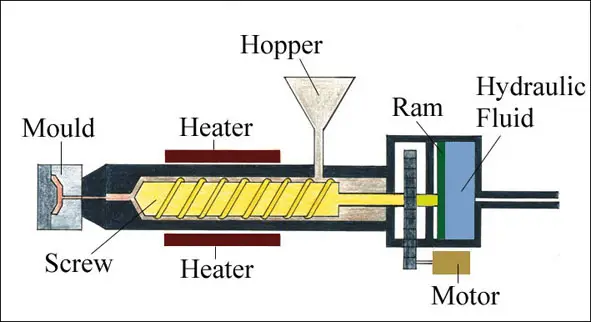

Granulated or powdered thermoplastic is fed from a hopper into the Injection moulding machine.

Stage 2

The Injection Moulding machine consists of a hollow steel barrel, cotaining a rotatign screw (Archemidial Screw). The screw carries the plastic along the barrel to the mould.

Stage 3

A Hydraulic Ram pushes the screw forward injecting the plastic through a spruce into a mould cavity. The mould is warmed before injecting plastic quickley to prevent it from harding.

Stage 4

Pressure is maintained for a short time during setting. the mould is left to cool before removing, the mould takes the shape of the cavity.

Comments

No comments have yet been made