resistant materials

- Created by: 15mlees

- Created on: 16-02-19 10:46

carbon footprint

What is a carbon footprint?

The amount of carbon dioxide, a greenhouse gas that is damaging to the environment, that is emitted during a process

What contributes to it?

- Transport methods

- Recycling

- The food you eat – the amount of plastic packaging it comes in, cows release methane

ecological footprint

What is an ecological footprint?

The amount of land that would be needed to make everything you use and dispose of your waste, measured in gha (global hectares per capita)

Why do developing countries have a low gha?

- They have less money to spend on luxuries

- People don’t travel as far

- They use fewer electric goods

social footprint

what is it?

a measurement that quantifies the social sustainability performance of an organisation

How can large companies improve their social footprint?

- Donating to food banks

- Contributing to local charities

- Stocking fair-trade products

- Paying employees equally

Who looks after health and safety in the workplace?

HSE ( health and safety executive )

energy generation

How are fossil fuels converted into electricity?

1. Burn fuel

2. Heat water to make steam

3. Steam turns turbine

4. Turbines turn generator

5. Electrical power

renewable or non - renewable

Renewable

Can be generated quicker than it is used up

Examples : Solar cells, wind, tidal, geothermal

Issue : Can only be harvested under certain conditions

Non-renewable

Limited amount of the resource

Examples : Fossil fuels

Issues : Releases greenhouse gases, destroys natural habitats, eye sore, polluting

Data collection

Primary data sources

- · Surveys

- · Visiting shops

- · Interviews

- · Questionnaires

- · Case studies

- · Focus groups

- · Product analysis

Secondary data sources

- · Online articles

- · Magazines

- · Books

- · Official data (e.g. government stats.)

- · Media (news, TV broadcasts)

ergonomics and anthropromatics

Ergonomics is the study of how equipment and furniture can be arranged in order for people to do work or other activities more efficiently and comfortably.

Anthropometrics is the study of human body measurements which are often used to make products more ergonomic (e.g. hand span, height, arm span, leg length)

Levers

a simple form of machine that changes the amount of effort/force needed to move a load.

Levers have three main parts:

effort - the amount of force applied by the user, also referred to as the input

fulcrum - where the lever pivots

load - the weight that needs to be moved, also referred to as the output

There are 3 types of levers...

First order Effort - Fulcrum - Load

Second order Effort - Load - Fulcrum

Third order Fulcrum - Effort - Load

1st class levers

1st class lever

When its input/effort is on one side of the fulcrum and its output/load is on the other

e.g. a see-saw

2nd class levers

2nd class lever

when its input/effort is at one end of the lever, its output is in the middle and fulcrum at the other end

e.g. a wheelbarrow

3rd class levers

3rd class lever

when its output is at one end of the lever, its fulcrum is at the other with its input in the middle

e.g. a stapler

mechanisms

What is a mechanism?

A device that uses forces and movement to make life easier for humans e.g. linkage, lever, pulley, gears, chain and sprocket

What is Mechanical Advantage (MA)?

The amplification of the input achieved compared to the output or the amount of help you get using a machiene in comparison to doing something with just human effort

MA = load ÷ effort effort = MA ÷ load load = MA x effort

Equilibrium: when the effort and load are equal M1 x D1 = M2 x D2

motions

Linear motion

Movement in one direction along a straight line

e.g. train

Reciprocating motion

A repetitive up and down or back and forth linear motion

e.g. saw

motions 2

Oscillating motion

The constant movement from side to side along a curved path

e.g. swing

Rotary motion

Movement in a circle around a fixed axis

e.g. clockhands

Linkages and cams

Linkages

Change the direction of a force or transform it into a totally different motion

CAMS

typically used to convert rotary motion into reciprocating motion

A cam mechanism has two main parts:

- a cam - attached to a crankshaft, which rotates

- a follower - touches the cam and follows the shape, moving up and down

reverse motion linkage

the input and output travel in the opposite direction with 1 fixed pivot point

parallel motion or push/pull linkage

the input and output travel in the same direction with 2 fixed pivot points

bell crank linkage

changes direction of the input by 90 degrees. This changes horizontal motion into vertical mtion with 1 fixed pivot and 2 moving pivots

crank and slider linkage

Changes rotary motion into reciprocating motion. It uses a crank with a fixed pivot to a connecting rod

eccentric cam

the follower moves up and down at a constant speed. Can be found in a steam train piston

pear shaped cam

The follower remains stationary for half a turn then gently rises and falls. These are used to make carousel horses rise and fall.

heart shaped cam

The follower rises and falls steadily with uniform velocity. There is no stationary period.

snail/drop cam

the follower remains stationary for half a turn before gently rising and suddenly falling

physical material properties

Physical property - description - material- Everyday uses

- Absorbency - The materials ability to soak up or retain liquid - Paper- Paper towels

- Resistance to moisture - The materials ability to prevent liquid and moisture permeating its surface - PVC - Waterproof coat

- Thermal conductivity - How easily heat energy can pass through a material - Aluminium - Foil, pots and pans

- Electrical conductivity - How easily electrical energy can pass through a material - Copper - Wires

- Fusibility - How easily a materials state can be altered to become a liquid - Silver - Solder

mechanical material properties

Mechanical property - description - material - Everyday uses

- Hardness - The ability to withstand scratching, cutting and abrasion - Varnished wood - Flooring

- Ductility - The amount a material can be permanently stretched/deformed when a force is applied - Copper - Wiring

- Elasticity - The ability to return to its original shape when a force on it is removed - Lycra - Sportswear

- Density - A materials mass per unit volume

- Malleability - The ability of a material for its shape to be permanently changed without breaking - Plastic - Moulds

- Toughness - The ability of a material to not break when a force is appliedto it suddenly - Steel - Car body panels

- Strength - A materials ability to withstand a constant force without breaking

strength testing

compression e.g. hitting with a mallet

tension e.g. pulling apart in different directions

shear e.g. cutting with scissors

torsion e.g. twisting

bending

a materials strength depends on its physical properties (how a material behaves under a specific, external condition) and mechanical properties (how a material behaves when being worked or shaped)

gears

Gears are wheels with teeth around the outside.

When several wheels are interlocked, they can transfer motion from one place to another, eg in some hand whisks or on bikes.

Smaller gears with fewer teeth turn faster than larger gears with more teeth. This difference in speed is called the gear ratio.

Gear ratio = number of teeth on driven gear ÷ number of teeth on the drive gear

output speed (rpm) = input speed (rpm) ÷ gear ratio

pulleys

a pair of grooved wheels with a belt running in the groove

when the belt is straight the pulleys move in the same direction

when the belt is crossed the pulleys move in both directions

velocity ratio = diameter of driven pulley ÷ diameter of the driver pulley

output speed (rpm) = input speed (rpm) ÷ velocity ratio

fibres

Natural

- Plant (cotton and linen)

- Animal (wool and silk)

Man - made

- Synthetic (polyester, LYCRA or elastane and nylon)

- Regenerated (viscoseand rayon)

textiles

Fabric is made from fibres - fine, hair like particles. Individual fibres are weak so they are spun and twisted together to produce yarn

woven :

- 2 sets of yarn interlaced together at right angles to each other

- vertical threads - warp threads and horizontal threads - weft threads

- all the edges fray except the sealed edge or selvedge

- the fabric has a grain due to the direction of the threads

knitted :

- the yarn travels back and forth across the width of the fabric, forming a series of interlocking loops that may be arranged in different ways

- make warm and stretchy fabrics

how fabrics are made

non - woven :

- made by pressing the fibres together sometimes using glue or heat where the fibres are melted together - sometimes referred to as a bonded fabric

- doesn't have a yarn - made from entangled raw fibres

felt :

- fibres are matted together by the interlocking the cuticles - hot water is used to shrink fibres together

blended and mixed fibres

blended fibres :

a combination of 2 or more fibres spun together when the yarn is made and they combine the properties of the different fibres

mixed fibres :

where 2 or more types of yarn are used when the fabric is woven

reasons for blending/mixing fibres:

- improves the appearance (colour and texture)

- improves the quality (makes the fabric more durable, stronger, longer lasting)

- to make it easier for care for (crease resistant)

- improves the handle of a fabric (drapes better, easier to sew, keeps shape better)

- makes it more cost positive

woods

Timber has different properties according to the direction of the grain. It can be burnt as fuel or broken down into fibres for use in manufactured timbers and it is biodegradable

appearance:

- staight grained

- colour consistency

- thickness consistency

- layered

- made of various small particles

properties:

- lightweight

- easily worked / machiened

- cost

- resistant to warping / cracking

softwood

Definition : comes from mostly evergreen trees which retain their leaves all year round. They're quick growing and take around 10 years to mature

Examples : larch - used in outdoor furniture, spruce - used for instruments, pine - used in furniture

Advantages : usually less dense - easier to work with, cheap, more sustainable as they grow quicker and can therefore be replenished quicker

Disadvantages : shorter life, can have more imperfections (knots) so it is weaker, poor resistance to decay

hardwood

Definition : comes from mostly deciduous trees which shed their leaves in autumn and have flat broad leaves. They're slow growing and take a long time to mature and be useable

Examples : ash - used in cricket bats, beech, oak - used in doors

Advantages : usually tough and durable, closed grained so have a good quality finish

Disadvantages : expensive, sources can be unethical, slow growing so less sustainable - contribute to deforestation

manufactured boards

Definition : manufactured in industry by gluing wood fibres or veneers together, versatile and popular, laminated boards, compressed boards, large sheets, consistant in appearance and quality

Examples : plywood, chipboard, MDF

Advantages : available in large sheets, more stable - less likely to warp, can be more sustainable

Disadvantages : dust particles are dangerous, edges can flake away, not as durable, less pretty

obsolescence

Planned obsolescence

when companies delibrately make their product brake after a short period of time

- computers

- phone batteries

- coffee cups

Percieved obsolescence

when companies convince their customers to throw away perfectly working products

- trainers

product evolution

Technology push

when research and development in new technology, drives the development of new products.

- cars - they've become electric, got touch screens, got engines that are better for the environment

Market pull

improvement or development of products due to the needs of society

the 6 Rs

Rethink

Reuse

Recycle

Repair

Reduce

Refuse

ACCESS FM

Aesthetics

Cost

Customer

Environment

Size

Safety

Function

Material

polymers

Plastics come from polymers which originate from crude oil - a finite resource

thermoplastics

- they can be moulded and remoulded multiple times by heating them up

- they are recycleable

- examples: packaging and acrylic

thermosetting plastics

- rigid / sturdy

- can't be reshaped

- difficult to recycle

- good insulators

- examples: plug sockets and pan handles

biopolymers

These are made from plants and veqetables which are an infinite resource

- they are non toxic

- biodegradable in soil

- but can't be recycled

- examples: polymorph and plastic cups

3D printing terminology

slicing - to slice an STL file ready for 3D printing a 3D drawing is taken and translated into individual layers

filament - the plastic material used e.g. PLA and ABS

PLA - Polylactic Acid - a biodegradeable plastic used to make 3D printed objects

ABS - Acrylonitrile Butadiene Styrene - a strong plastic used to make 3D printed objects

alignment - how products are printed

Gcode - the code sent to the 3D printer after slicing

FDM - fused deposition modeling - filament is deposited in single layers that fuse together to create a 3D object

3D printing terminology 2

nesting - printing multiple objects on a single bed at once

rafts and supports - supports the print and prevents warping i.e. when printing a hollow hemisphere

brims - adds an edge to the print to make it adhere better to the bed

skirts - a perimeter around the first layer that ensures the filament is flowing before starting the first layer

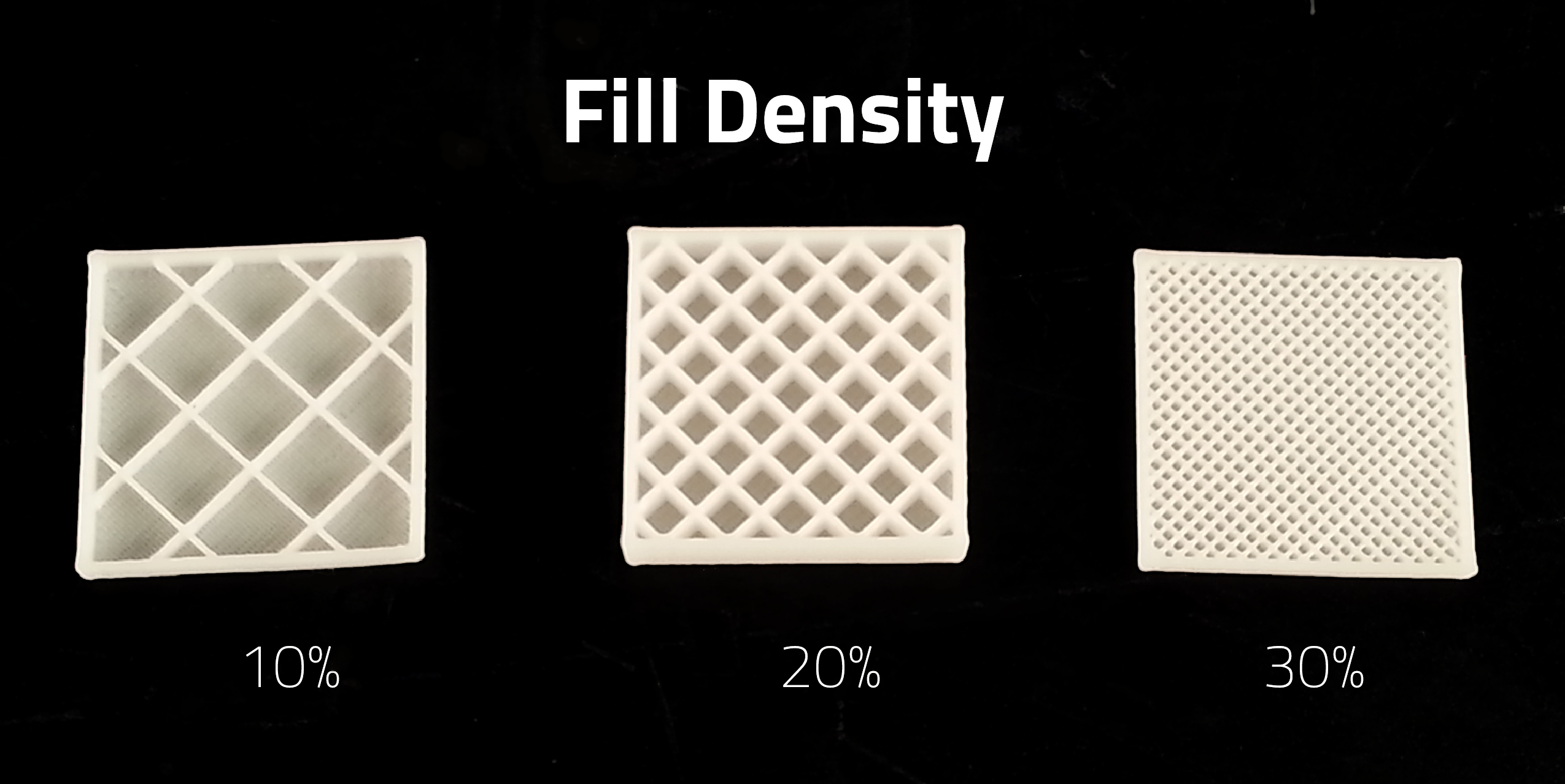

density - the infill of a design - relates to how strong the product will be - infill paterns include honeycomb or triangles

positives and negatives of 3D printing

- makes healthcare more affordable and efficient - custom polymer implants can be made much quicker and out of cheaper materials

- can be used to create affordable housing

- can be used to create emergency shelters quickly

- can reduce the cost of everyday items

- can be a very long design process e.g. if the infill patern is complecated

- produces dangerous chemical particles

design strategies

- a guide to how the design process takes place

- important as it avoids design fixation

- allows specialists in different material areas to collaborate

User Centred Design

- an approach where the needs and wants of the end user are considered extensively at each stage of the design process

advantges

- the end user feels listened to

- its more likely that the final product will meet the users' expectations

disadvantages

- it requires extra time to meet and hold discussions with users and then alter the design

- the design could become too focused on a particular group of people and become unviable to sell to the wider public

design strategies 2

Iterative Design

- a cyclic approach where each iteration is tested and evaluated, changes and refinements are made, leading to a new iteration

advantages

- problems with the design will be found and dealt with earlier

- encourages focus on the most critical aspects of a product's design

- user feedback is constantly being gathered

- evidence of progress can be easily provided to stakeholders

disadvantages

- designers can lose sight of the bigger design picture by becoming too focused on the current iteration

- time consuming as lots of prototypes have to be made

design strategies 3

Systems Thinking

- often used when designing electronic, mechanical and mechatronic systems

- a top down approach that starts with an overview of the overall system and the details of the individual components are considered later

advantages

- doesn't require highly specialist knowledge to design the overview of the system

- makes it easy to communicate how the system will work to non technical specialists

- the system is designed in blocks so it is easier to find errors or faults in the design

disadvantages

- the block based approach can lead to the use of components that aren't necessary which can lead to larger systems and extra cost

electronic systems

input device: take a real world signal e.g. light and turn it into an electronic signal e.g. current

process: alter the electronic signal to create functions e.g. microcontrollers - a small computer programmed to add functionality such as timing and counting

driver: increases the signal going into the output stage so they can draw the required amount of current to work effectively

output device: take an electronic signal and turn it into a real world signal e.g. speakers

designers

Harry Beck

- designed the london underground map in 1931

- influenced by the layouts used in electronic schematics

- his design has been widely copied for other public transport systems around the world

Charles Rennie Mackintosh

- a scottish architect

- an influence on the Art Nouveau movement

- influenced by modernist and japanese architecture

- designed The Lighthouse building in Glasgow

Gerrit Rietveld

- a dutch architect and furniture designer

- influenced by the De Stijl design movement which aimed to simplify design to vertical and horizontal lines along with only using black, white and primary colours

- designed the famous Red and Blue Chairin 1917

companies

Alessi

- produces everyday houseware and kitchen utensils designed by famous names

- many of its products are in the post modern style

- many products are made from stinless steel or polymers

- e.g. the Juicy Salif lemon squeezer designed by Philippe Starck

Dyson

- a british design engineering company formed by James Dyson in 1991 as a way of bringing his new bagless vacuum cleaner invention that don't lose suction to the market

- by 2001 over 47% of all vacuum cleaners sold in the UK were dysons

- dyson has diversified to include heaters, bladeless fans and hairdryer in their product line

Apple

- a Californian company that initially sold extremely innovative personal computers

- later they produced the aesthetically iconic iMac G3, the iPod and the iPhone which combined elements of both the G3 and the iPod with a touch screen

fair trade

a movement that works to help people in developing countries get a fair deal for the products that they produce

many consumers like to buy fairtrade products as it fits with their values and principles

producers in developing countries

- are paid an agreed minimum rate for many products which gets paid even if global prices fall

- recieve a Fairtrade premium payment that they can use to invest in areas such as local education and healthcare

a product that meets fairtrade standards has the Fairtrade Certification Mark

a product that meets fairtrade standards has the Fairtrade Certification Mark

issues in the manufacture of products

designers must consider how the raw materials used in their product are sourced and transported

Ecological Issues

- using wood in your design causes deforestation which results in the loss of habitats and impacts climate change

- using raw materials such as metal ores results in mining which can cause erosion and contamination of soil

- using plastics requires drilling for oil which could lead to oil spills which effects widelife health

Social Issues

- workers in other countries aren't protected by safety legislation

- factories can increase atmospheric pollution which is linked to severe respiratory illnesses in locals such as lung cancer and asthma

- chemicals and other industrial waste is released into oceans causing oceanic pollution which negatively impacts marine life and habitats

briefs and specifications

design brief

- a short description of the design problem and how it is to be solved

- the design situation is usually ontline first

- typically written as a few sentences or a short paragraph

- they can be modified and altered if it becomes clear it doesn't meet the users needs

design specification

- a list of measurable design criteria that the product must meet

- provides much more detail on the specific requirements of the product

- should include criteria related to the materials, cost, aethetics, function, ergonomics, quality and components to be used

manufacturing specification

- contains the information needed to successfully maufacture the design

- i.e. the scale of production, a description and drawing of the final design with assembly and construction details, materials and components needed and how quality will be ensured

communication of ideas

- sketching

- 3D sketching

- exploded drawings

- annotation - materials, colours, finishes, cost, safety, processes used, difficulty, inspiration and opinion

- working / orthographic drawings - plan (top), front and side elevation

- system and schematic drawings

- mathematicla modelling - simulates real life situations

- computer based tools - vitual models

- physical modelling - card, toile, bnreadboarding

- film clips

computer based tools

Digital tools have enabled designers to ...

- communicate with clients and stakeholders anywhere in the world

- hold virtual meetings with other designers

- present ideas to clients without being with them

- draw, model and simulate design ideas before making them using CAD/CAM

- create online data tables which manage calculations such as cost quickly and accurately

This is much cheaper and less time consuming than travelling to speak with them face to face and reduces material waste

prototype development

Prototypes are full-sized, actual versions of an intended product whereas models are usually scaled down representations

Prototypes allow designers to see how a product will look and function and gather feedback from clients. They ensure that problems with a design are found early before lots of time and money is spent on materials and manufacture

Evaluating Prototypes - what to consider

Cost

Aesthetics

Function

Ergonomics

Quality

User

Environment

paper and board

Different types of paper /card are different thicknesses and are suitable for different functions

- thinner paper (low gsm) used for tracing and flyers

- in the middle is used for packaging

- thicker paper is used for printing and highquality packaging

Standard sizes

- A6 is the smallest size, the area doubles with each size, up to A0

- the higher the gsm, the thicker the paper

Source and disposal

- paper and card are made from cellulose fibres derived from wood and grasses

- chemicals are added to produce the required texture and surface finish

- most paper and card can be recycled - they are also biodegradeable - but recycled paper can't be used to make food packaging

- composite materials e.g. foil - lined board cannot be recycled

metals

making metal

- metal ore is extracted forom the ground by mining or quarrying

- the metal is refined from ore by large scale industrial processes e.g. electrolysis

- metals are then typically meltedand either cast into products or shaped into stock forms

- metals can be recycled by melting them down and reprocessing them into new products

ferrous metals

- these metals all contain iron and are the most commonly used metals

- they generally have a melting point of 1600C or higher and are silver-grey in colour

- most are prone to rusting and corrosion and are magnetic

- examples: cast iron, low carbon steel, high carbon steel

metals 2

non ferrous metals

- these metal don't contain iron

- they typically have good corrosion resistance but they do tarnish and aren't magnetic

- examples: aluminium, copper, tin, zinc

common alloys

- most metals are used as alloys

- an alloy is a mixture of 2 or more metals, ceated by melting the metals and adding them together and they can be ferrous or non ferrous depending on their components

- examples: brass, stainless steel, high speed steel

stock forms

- metals can come in the form of sheets, rods, bars and tubes

- it requires lots of energy to reform metal so designers try to use standard shapes and sizes

making polymers

- polymers are chains of similar small chemical units called monomers

- most commonly used polymers are synthetic and made from non renewable resources and aren't normally biodegradable

- they are made when crude oil is separated using fractional distillation and can be broken down into monomers by cracking

- some polymers break down slowly and become weaker when exposed to UV light in sunlight but chemical stabilisers can be added to the material to resist this degradation

polymers 2

Thermosetting Polymers

- the polymer chains are interlinked with permanent chemical bonds

- commonly available in liquid form (resin) or as powders but these must be cured or reacted with chemicals to create the polymer and cannot soften when heated but may char

- typically end up being disposed to landfill

- Examples: Epoxy resin, Phenol formaldehyde

- Uses: coatings and adhesives

Thermoforming Polymers / Thermoplasics

- soften when heated so can be reshaped multiple times

- available in sheets, films, foam, pellets / granules, powder and rods

- can be recycled if sorted into their different types

- Examples: PVC and HIPS

- Uses: packaging and pipes

modern materials

Materials with improved properties are constantly being developed

Often developments in materials involve altering a material to perform a particular function. This can be done by coating the material with a nanomaterial

Metal foams

- made from metal containing gas filled pores and look like a sponge

- have the physical properties of the metal but canbe 75-95% lighter in weight

- Uses: sound damping and crash resistant structures

Graphene

- a form of carbon where the atoms are arranged hexagonally in a flat 2D layer, 1 atom thick

- its 200 times stronger than steel, flexible, transparent and is a good conductor

- Uses: solar cells and touch panels

modern materials 2

Smart materials

- they have a property that changes in response to an external stimulus e.g. light or pH

- shape memory alloys change to their original shape when they are heated e.g. in spectacle frames if they are accidentally bent they can be heated and returned to their original shape

- thermochromic pigments change colour in response to temperature

- photochromic pigments change colour in response to light levels

Composites

- they combine the properties of 2 or more materials

- unlike an alloy the materials in a composite are not mixed chemically and the separate materials can be seen under a microscope

- they can't normally be recycled as the materials can't easily be separatedso they are normally disposed of in landfill

- Examples: fibreglass and CRP

modern materials 3

Nanomaterials

- made up of particles less than 100 nanometres in size

- nanomaterial coatings for glass and fabrics can repel dirt or water

Technical Textiles

- manufactured for performance properties rather than visual appearance

- made from fibres spun from materials with the required properties and woven into fabric

- conductive fibres allow circuits to be incorporated into fabrics and can be used to make temperature controlled clothing or intergrate lights into emergency clothing

- microfibres incorporating micro-encapsulation are used for socks and underwear to reduce body odour

finishing materials

Purpose of finishing

- to improve function or aesthetics

Metal based materials

- dip - coating

- powder coating

- galvanising - dipping in molten zinc

Polymers / Plastics

- polishing

- printing onto

Timber based materials

- painting

- varnishing

finishing materials 2

Textile based materials

- block and screen printing

- dye

- stain resistant finishes

Papers and boards

- printing

- embossing

- UV varnishing

selection of materials

Factors affecting material selection

- the material must have functionality - the mechanical and physical properties needed for the design

- designers also consider the ease of working

- aesthetics

- environmental considerations - is the material recyclable?

- availability of materials

- cost

- social factors

- ethical considerations - only using fairtrade and sustainably sourced products

- cultural factors such as fashion

working with materials

The properties of some materials can often be enhanced to make them more suitable for specific applications. The method used to enhance the properties depends upon the type of product, what it is made from and what properties are needed.

How material properties can be modified

- seasoning (drying) timber reduces the risk of warping

- annealing (heating) metals increases the malleability

- additives can be added to paper to prevent moisture transfer

Reinforcement

- this allows just the part of the product that needs greater strength or stiffness to be enhanced without affecting the weight and cost too much

- this can be done by bending, folding and lamination

scales of manufacture

The quantity of identical products to be made has a significant effect on the equipment selected to manufacture the products

One - off / bespoke production

- one product is made at a time

- takes a long time for each product tobe made and a high level of worker skill

- cost of each product is high

- Examples: a tailored suit or satellite

Batch production

- a group of identical products are made together

- some processes may be automated or dedicated jigs might be used

- the cost of equipment set up is high so more products have to be made to bring the cost per item made down

- Examples: furniture and clothing from high street stores

scales of manufacture 2

Mass production

- large quantities of identical products are needed

- the product goes through different processes on a production line

- the equipment is only used to make that product again and again

- most processes are automated with dedicated jigs and fixtures

- the cost per product is lower than batch manufacturing

- Examples: Cars

Continuous production

- used to manufacture materials or chemicals that are subsequently used in the making of other products

- very large quantities are produced using a production line that runs 24hr/day, 7 days a week

- the equipment is only used to make that product

- the processes are fully automated with dedicated jigs and fixtures

- the initial set up cost is very high but the cost per product is low compared to other methods

- Examples: petrol and steel

quantity and equipment

As the quantity of products to be made increases it is more likely there will be discounts for buying materials in bulk or labour costs will be reduced by moving from hand tools to automatic machienes

Material management

- designers try to use a stock form of material to minimse the amount of machiening needed

- to eliminate waste from cutting, repeating designs may be tessellated or shapes may be nested together - digital lay planning is the use of computer software to arrange a pattern on a material

manufacturing processes - timbers

Types of Manufacturing Process

- Wasting involves taking away material

- Addition processes involve adding material

- Deforming and Reforming involve changing the shape without gain or loss of material

Wasting Proccesses

- Saws: tenon, coping, band, circular

- Chisels: bevel-edged, gouge

- Planing: shaving off thin layers of wood

- Sanding: abrasive paper, belt sander

- Cut on a laser cutter

- Turning on a lathe

- Drilling

manufacturing processes 2 - timbers

Addition Processes

- PVA adhesive can permanently bond timber together

- Laminating curved wooden shapes

Deforming and Reforming

- strips of timber can be bent by heating them in steam until pliable, shaped round a former and clamped in place until it cools

- Laminating

manufacturing processes - polymers

Wasting Processes

- thin sheet polymers can be sawn

- drilling

Addition Processes

- thermoplastic parts can be welded together

- polymers can be joined permanently by using solvent cement - dissolves the surface of the polymer parts so they can mix together and form a joint as they solidify

- 3D printing

Deforming and Reforming

- line bending

- vacuum forming

- yoke moulding

Production aids

They are required to achieve accuracy and precision of product manufacture but are only really used when manufacturing by hand

Jigs

- custom made tools designed to achieve accuracy, repeatability and interchangeability

- used to ensure that parts of a product are always made exactly the same

Templates

- used to draw a shape onto material which can then be cut around

- useful when a large number of complex identical shapes have to be cut

- often made from inexpensive material

Patterns

- a type of template widely used in the textiles industry to trace the parts of a garment onto fabric before it is cut and are usually made from paper

ensuring accuracy

Accuracy: the degree of closeness of a measurement to its true value

Precision: how repeatable or reproducible the measurement is

Being inaccurate can result in...

- a product that is not fit for purpose

- products having to be remade

- deadlines not being met

- extra costs

Tools that improve accuracy

- jigs, templates, patterns

- using CAD and CAM

tolerance and quality

Tolerance: the permissible limits of variation in the dimentions or physical properties of a manufacture product or part

- usually given on product specifications or drawings

- needed so manufacturers understand the importance of the dimensions they've been given

- taking tolerances into account reduces the likelihood of improper fits

Quality control

- product orientated

- about testing and checking that a product meets the specification or set standards

Quality assurance

- process orientated

- about putting systems in place that ensure the quality of the processes used to manufacture a product

new and emerging technologies

Impact on industry

New and emerging technology impacts the deign and organisation of the workplace

- automation in manufacture can help to increase the efficiency of production

- the increased use of CAM and rapid prototyping equipment means that fewer hand tools and workers are being used which allows greater accuracy and consistency of manufacture

Impact on employment

- increased automation will result in fewer jobs being available

- the increase in the use of CAD and CAM has resulted in fewer jobs for skilled hand machiene workers but more jobs for people trained in the use and maintenance of CAM equipment

new and emerging technologies 2

Impact on enterprise

Crowd funding - raises awareness and money for a project or idea

- the internet has made crowd funding easier to implement

- useful for independent people or start up businesses who might struggle to access more conventional sources of funding

Virtual Marketing and Retail

- the use of web based marketing techniques e.g. using social media, email advertising

Cooperatives

- a business or organisation that is run jointly by its members who share the profits made

- they benefit from the buying power of its entire membership and its democratic structure and are easy to set up

Fairtrade and Planned obsolescence also impact on enterprise

new and emerging technologies 3

Impact on production

CAD - the use of computer software to produce designs (2D or 3D) for products

- its extremely accurate and easy to modify or revise

- files can be shared very quickly or imported into presentations

- 3D models can be rotated and viewed from different angles

- can be expensive

- appropriate ICT hardware is needed to run the software

- needs specialist training

CAM - the use of computer software to control machiene tools to manufacture products

- consistent, precise and accurate, efficient

- complex shapes can be produced much more easily than when manufacturing by hand

- increases the speed of manufacture

- initial set up costs can be high

- operators must be trained which is time consuming and expensive

new and emerging technologies 4

Impact on the environment

- new technologies can be used to reduce pollution such as electric car engines

- CAD and CAM reduce waste

Impact on culture

- changes in fashion and trends can be affected and influenced by new and emergent technologies like social media

Impact on society

- phones have made it easier to communicate but also have meant people talk directly less

- products should be developed so that they do not have a negative impact on others

Inclusive design: designing products that can be used by everyone without any special adaptions

Exclusive design: when products are designed for a particular group of people

Related discussions on The Student Room

- Oxford Materials PhD applicants 2021-2022 »

- Material Selection for Tents »

- Help mechanics »

- Can someone help me understand these definitions in mechanics? »

- Accreditations »

- Engineering Foundation year (help!!) »

- A-level maths help :( »

- A level physics electricity question (7) »

- As maths »

- Mechanics help »

Comments

No comments have yet been made