Chemistry C1 (part 2)

0.0 / 5

- Created by: lucylulou

- Created on: 15-05-16 18:40

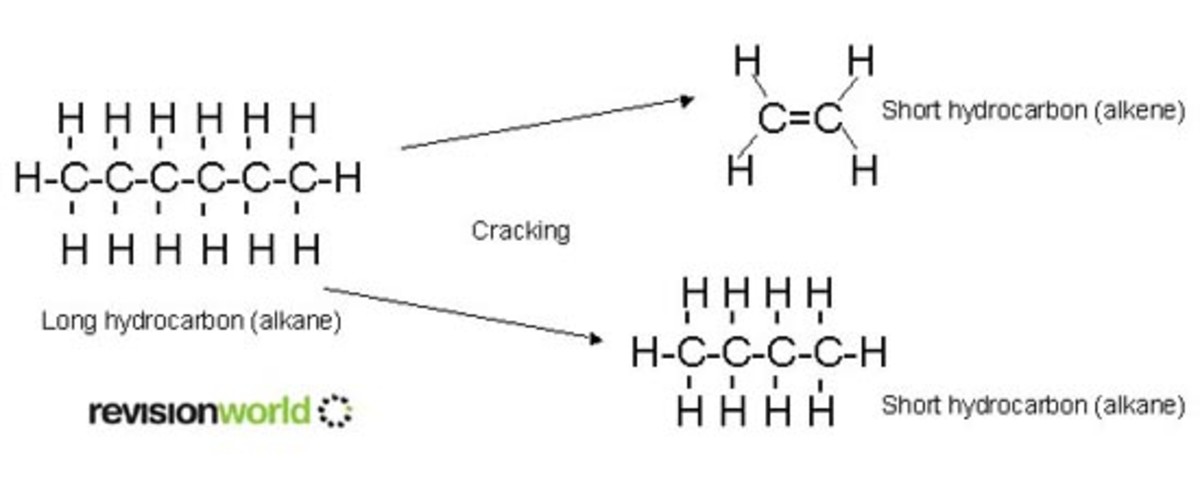

Cracking Crude Oil

- Long-chain hydrocarbons form thick gloopy (viscous) liquids eg. tar > not that useful

- Most longer molecules produced from fractional distillation are turned into smaller ones by the process of cracking

- Some products from cracking are useful as fuels, eg. diesel > cracked to form petrol, paraffin

- Ethene can also be produced > needed for making plastics

- Cracking is a thermal decomposition reaction (breaking molecules down with heat)

- First the long-chain hydrocarbon is heated to vaporise it > passed over a powdered catalyst (aluminium oxide) at around 400 - 700ºC

- The long-chain molecules split apart or 'crack' on the surface of the catalyst

- Most products of cracking are alkanes and alkenes.

1 of 4

Alkenes & Ethanol

- Alkenes > hydrocarbons > double bond between 2 carbon atoms in their chain C=C

- They're unsaturated because they can make more bonds - double bond can open, allows the 2 carbon atoms to bond with other atoms

- Alkenes: ethene (2 Cs), propene (3 Cs), butene (4 Cs) general formula: CnH2n

- Test for alkenes > add to bromine water > the alkene will decolourise the bromine water > orange to colourless (double bond is opened and forms bonds with bromine)

- Ethene (C2H4) can be hydrated with steam (H2O) with a catalyst > produce ethanol

- atm. it's a cheap process > ethene is fairly cheap, not much wasted. Ethene's from crude oil (non-renewable) > will run out > therefore the process will get more expensive

- Ethanol can also be produced by fermentation of sugar (renewable) + yeast

- sugar -> carbon dioxide + ethanol

- Needs a lower temp. and simpler equipment. It's cheap fuel

- Disadvantages: the ethanol produced isn't very concentrated, it has to be distilled and purified

2 of 4

Alkenes > Polymers

Alkenes > polymerisation > polymers

- Joining together lots of small alkene molecules (monomers) to form very large molecules called polymers

- Eg. join up lots of ethene molecules > produce polyethene

- Physical properties depend on: what it's made from and temperature & pressure of polymerisation

- eg. Polyamides are stronger than polyethene. Polyethene made at 200ºC with 2000 atmospheres pressure > flexible, low density. Polyethene made at 60ºC and low pressure + catalyst > rigid, dense

- Light, stretchable polymers > plastic bags. Elastic polymer fibres > LYCRA fibre > tights. Waterproof coatings for fabrics (polymers). Dental polymers > resin tooth fillings. Polymer hydrogel wound dressings > keep moist. Biodegrable packaging > polymers & cornstarch. Memory foam (smart material) > polymer gets softer when warmer.

- Most polymers arn't biodegradable > hard to get rid of > contribute to landfill or recycle

- Polymers are cheaper than metal, but as crude oil runs out > get more expensive

3 of 4

Plant Oils

Some fruits and seeds contain lots of oil > extracted for food/fuel

- Plant material crushed > pressed between metal plates > oil squeezed out

- OR use a centrifuge to separate oil from crushed plant OR use solvents

- Distillation refines oil and removes water, solvents & impurities

- Vegetable oils (used in food) have a very high energy content and contain nutrients & essential fatty acids (metabolic processes)

- Benefical:

- higher boiling point than water, cook foods at higher temp. and faster

- gives a different flavour

- get more energy from foods cooked in it

- Vegetable oils (eg. rapeseed & soybean oil) can be turned into fuels (provide lots of energy)

- Useful fuel from vegetable oils > biodiesel.

- Similar properties to ordinary diesel - burns in the same way, so it can be used to fuel a diesel engine.

4 of 4

Related discussions on The Student Room

- Energy dissipated »

- Maths for economists - constrained maximisation questoin »

- Senior Physics Challenge 2022 »

- circle question help »

- Learning a 2nd language »

- Paramedic science- time out after college »

- best way to revise maths »

- Isaac Senior Physics Challenge 2024 »

- Learning a 2nd language »

- Senior Physics Challenge Isaac Physics »

Similar Chemistry resources:

0.0 / 5

0.0 / 5

1.0 / 5 based on 1 rating

3.0 / 5 based on 1 rating

0.0 / 5

0.0 / 5

0.0 / 5

0.0 / 5

0.0 / 5

0.0 / 5

Comments

No comments have yet been made